Engineering the Perfect Glass Touch Screen for Superior Experience

What Makes a Glass Touch Screen So Appealing?

Why Are Glass Touch Screens Becoming the Standard for Modern Devices?

Glass touch screens have turned into a hallmark of current tech. They provide not just visual charm but also top-notch performance. Their slim style and upscale finish boost how people view their gadgets, whether smartphones, tablets, or smart home setups. The sharp surface delivers a refined appearance that’s tough to match with other substances.

When it comes to toughness of the cover lens, glass far exceeds plastic options. It features strong resistance to scratches. Plus, it handles regular use without visible damage. This quality positions it as a perfect pick for gadgets designed for everyday grip.

Just as vital is the quick response of a glass touch screen. Its even surface enables fast and precise touch actions, like tapping, swiping, or pinching. This smooth handling greatly boosts user contentment. As a result, routine chores seem effortless.

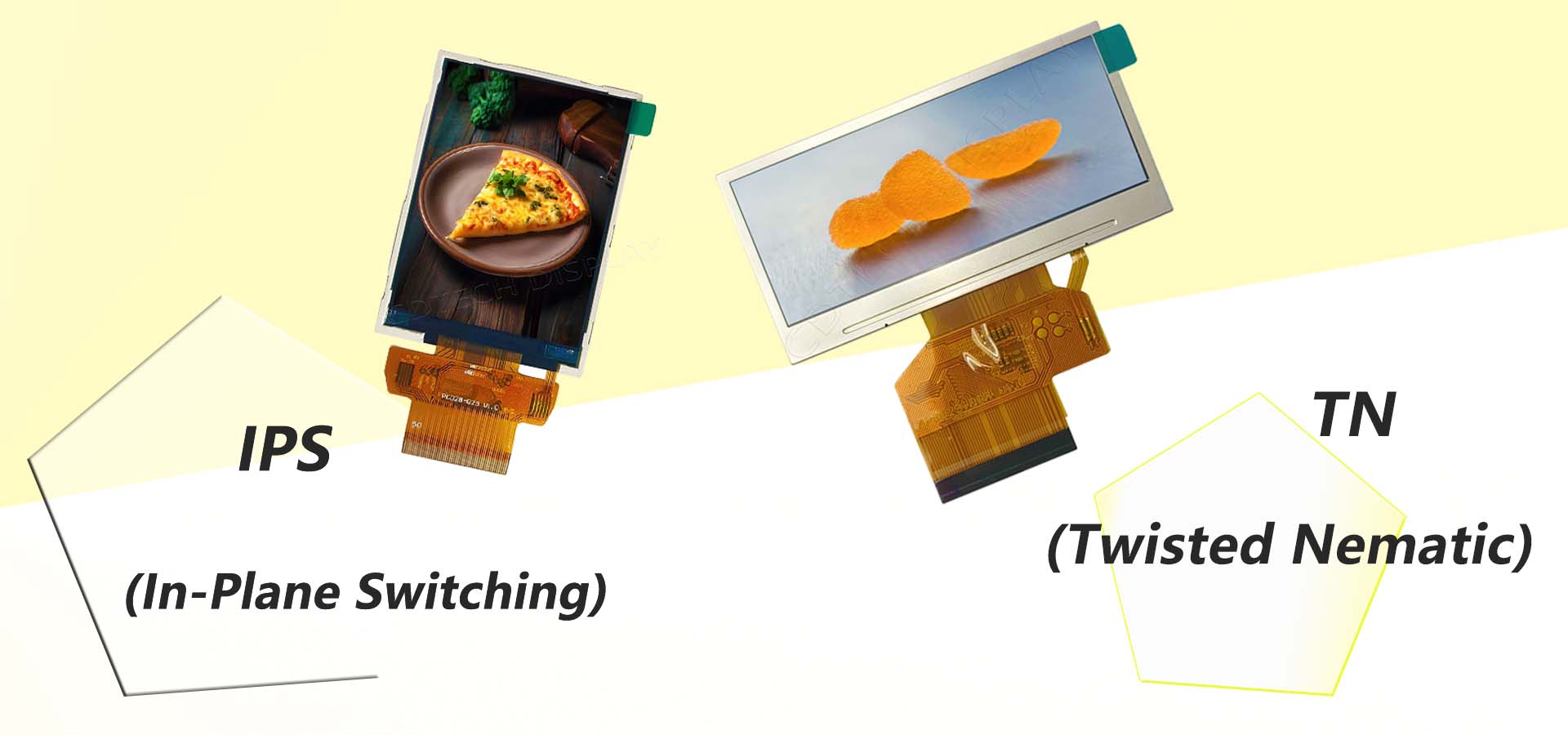

How Does Glass Improve the Touch Experience Compared to Plastic?

Next to plastic screens, glass touch screens deliver much better visual sharpness. Colors look brighter. Details stand out clearer. This upgrade greatly improves the viewing for users.

The even slide of a glass surface also creates a nicer feel under the fingers. The same goes for stylus use. Navigation comes across as simple. Plastic, on the other hand, might bend or wear down as time passes. Glass, however, keeps its shape and evenness. It ensures steady operation for a long time.

Furthermore, its ability to fight wear and bending keeps the screen quick to respond and easy on the eyes. This holds true even after heavy use.

The Engineering Behind a High-Quality Glass Touch Screen

A top-notch glass touch screen comes from aligned engineering choices instead of just one part pick. Materials, touch methods, joining techniques, and structural layout need to team up as a full setup.

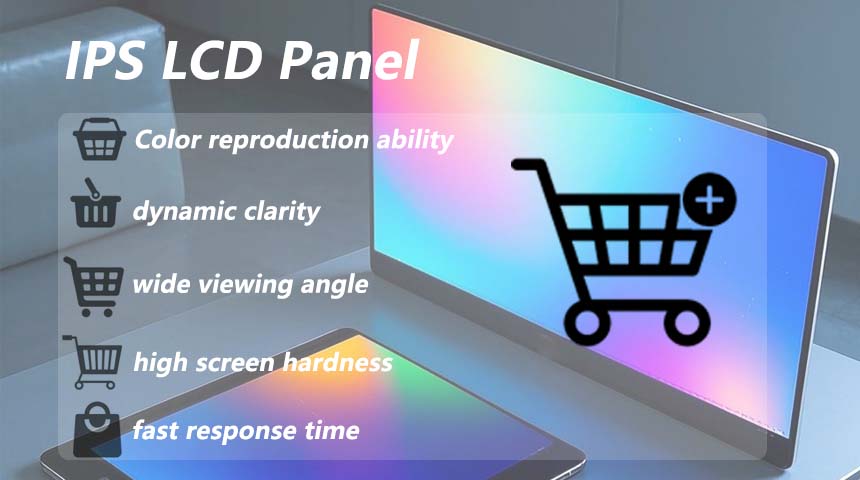

High-performance glass touch screens usually employ chemically toughened glass to boost surface toughness and shock resistance. This method raises pressure stress on the glass top, making it better at handling scratches and breaks in routine use. In settings with shakes, regular touches, or heat shifts, picking materials straight affects item lifespan and upkeep expense.

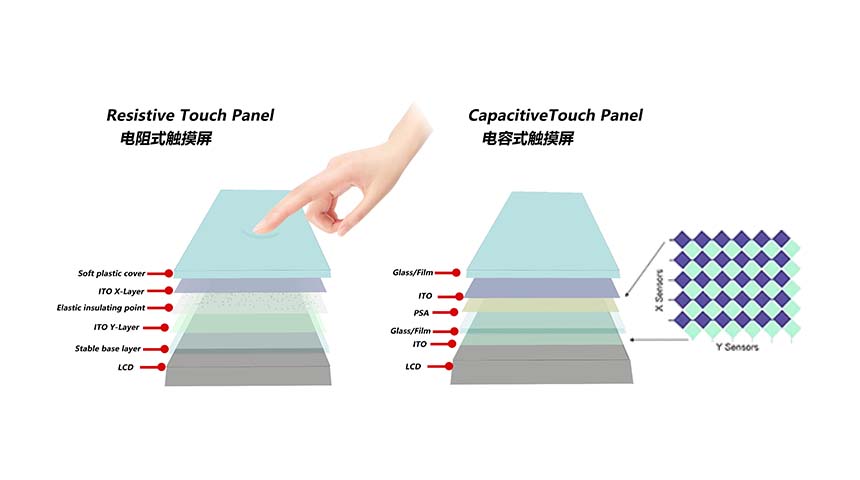

Touch entry mostly gets handled via projected capacitive (PCAP) tech, which spots shifts in an electric field over the glass top. Unlike resistive setups, PCAP tech gives greater sensitivity, multi-touch options, and steady work through guarding glass layers. These traits suit it for consumer gadgets and factory human-machine controls.

Glass depth has a key part in weighing reaction speed and strength. Slimmer glass boosts touch feel but raises break chance, while bulkier glass improves physical power but cuts down on reaction. Top designs match glass depth to use needs like shock resistance rules, planned touch rate, and surroundings pressure.

Design Considerations for Superior User Experience

What Role Does Thickness Play in Touch Sensitivity?

The glass thickness affects both its quickness and sturdiness. Slimmer glass often means quicker touch replies. It does so without losing firmness. Still, balance is key. If too slim, breakage risks rise. If too heavy, quickness might drop.

The best setup makes sure the glass can take hits. At the same time, it keeps high touch precision and clearness.

How Do Anti-Fingerprint and Anti-Glare Coatings Enhance Usability?

To lift user ease more, special coatings go on glass touch screens. Oleophobic layers push away oils. They cut down on fingerprint marks. So, the screen stays neat and bright during often use.

Anti-glare finishes spread out bounced light. Screens become simpler to see in strong light or direct sun. This helps a lot for outside tasks or spots with harsh overhead beams.

Customization Options for Different Applications

Can Glass Touch Screens Be Tailored to Specific Needs?

Yes, glass touch screens give plenty of tailoring choices. These fit particular gadgets or sector needs.

We offer customized LCD OD, LCD AA, FPC OD, backlight option. Whether you seek a special form, exact size measures, or unique border styles, these can adjust to your setup.

Where Are Glass Touch Screens Commonly Used Today?

Consumer Electronics

In daily tools like smartphones, tablets, laptops, and smart home items, glass touch screens bring easy handling and vivid sights. Their strength and grace make them a must in consumer gear.

Industrial Equipment

Glass touch screens see wide use in work settings too. They fit into control boards, kiosks, or medical displays. Their solid build and clear view handle tough spots. Precision stays intact.

Automotive Interfaces

Newer cars depend more on touch screens for entertainment setups, map shows, and dash controls. Here, the mix of neat looks and solid work lifts both style and ease while driving.

CDTech: Innovating the Future of Glass Touch Screens

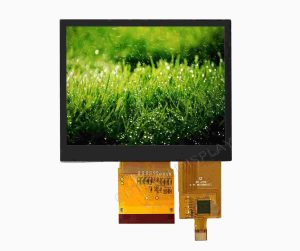

Who Is CDTech and What Sets Their Products Apart?

At CDTech, we focus on forward display fixes that blend latest touch methods. Our goal is to supply high-grade glass touch screens. They mix fine optical sharpness with top strength.

We get that various sectors face different needs. That’s why our items get built to shine in varied spots. They offer pure visuals and rapid replies.

What Types of Products Does CDTech Offer in This Field?

Projected Capacitive (PCAP) Touch Screens

Our PCAP touch screens bring multi-touch skills with fine accuracy. Made for quickness and simple handling, they back detailed moves like swiping and pinching. No lag occurs.

Optical Bonded Display Modules

For outside or bright-light areas, we provide optical bonded displays. They cut back on reflections and lift sight. These units suit work uses where sun clarity counts.

Custom Solutions for OEM Applications

We give complete custom fixes to match your needs. If you want set sizes or built-in traits for your system, our skills let us deliver more derivative solution for glass touch screen.

FAQ

Q: What’s the difference between capacitive and resistive touch screens?

A: Capacitive screens use the electrical properties of your finger to detect input, offering better sensitivity and multi-touch support compared to resistive screens that rely on pressure.

Q: Can glass touch screens be used outdoors or in harsh environments?

A: Yes, when combined with optical bonding and anti-glare coatings, glass touch screens perform well outdoors or in industrial settings by improving visibility and durability.

Q: Are glass touch screens compatible with gloves or styluses?

A: Many modern glass touch screens support glove or stylus input through enhanced capacitive sensing technologies or special settings designed for different use cases.

2026-01-01

2026-01-01  11:50

11:50