How to Evaluate & Screen Reliable Capacitive Touch Panel Suppliers

Understanding Capacitive Touch Panel Suppliers

What Makes a Capacitive Touch Panel Supplier Reliable?

When assessing capacitive touch panel suppliers, dependability stands out as a key feature. A solid supplier shows solid know-how in capacitive touch tech and production methods. This covers skills in sensor creation, controller IC setup, and joining methods such as air or optical bonding.

A trustworthy supplier also boasts a solid history of providing steady product quality and output across lots and through years. This matters a lot for sectors needing stable long-term supplies, like medical, automotive, and industrial automation.

Moreover, meeting global certifications and sector standards shows that the supplier sticks to widely accepted quality handling practices. These approvals confirm that the firm uses organized steps in design, making, and quality checks.

Why Is Supplier Evaluation Crucial in the Touch Panel Industry?

Picking the best supplier affects each stage of your project. A thorough review guarantees lasting product steadiness and fit with final user needs. For example, choosing a panel that works well with your LCD module and handles environmental factors cuts down on redesign work.

Good supplier checking also lowers chances of holdups or flaws in making. Wrong talks or weak quality checks can lead to expensive mistakes or late finishes. Plus, a good supplier tie boosts overall project expense, wait time, and user happiness.

Key Criteria for Evaluating Capacitive Touch Panel Suppliers

How Important Is Manufacturing Capability in Supplier Selection?

Production ability directly shapes the supplier’s skill to meet your needs. This means looking at the output size, degree of machine use, and cleanroom rules for parts sensitive to dirt. Suppliers that run their own CTP (capacitive touch panel) line give better grip on process steadiness.

It helps to learn if the supplier can manage special specs and provide size options for both test and large-run making. Also, check if main production steps happen inside or get handed off, since inside work often means smoother teamwork and quicker replies.

What Quality Control Measures Should You Look For?

Strong quality checks make sure of even performance and cut down on flaw numbers. Seek suppliers who give full tracking from starting materials to end goods and who use light-based check systems and power tests at different making points.

Approvals like ISO 9001 matter because they point to a grown-up quality system.

How Does R&D Capability Affect Product Innovation?

Strong R&D skills let suppliers create fresh features suited to buyer wants. Suppliers with their own engineer groups can give design tweaks and custom help right at the start of the project.

Options like multi-touch work, water/glove use, and stylus aid all come from solid R&D efforts. Our touch screen customization services support thick cover lens, operation with water or gloves, and the use of active or passive pens. Also, the skill to link with various display types (TFT LCD, OLED) relies much on steady R&D spending.

Communication, Logistics & After-Sales Support

Why Is Transparent Communication Essential When Working With Suppliers?

Open and quick talk is key to good teamwork. Right technical papers make sure of easy fitting into your end item, mainly when handling tricky link rules like I2C or USB.

Regular news on wait times, possible problems, or design shifts aid you in handling risks well. Skill in languages and fast replies also help avoid mix-ups that can mess up schedules.

What Should You Know About Delivery Terms and Lead Times?

Shipment steadiness depends on things like test vs. large-run wait times, stock on hand, and send options. Suppliers that give varied shipping rules like FOB, CIF, or DDP aid in matching logistics to your project’s wants.

Options for extra stock can prove very useful for rush jobs or sudden need jumps.

How Valuable Is After-Sales Support in Long-Term Partnerships?

Post-sale help makes sure of ongoing wins after first shipment. Look for suppliers who give tech aid during fitting or software fixes after setup.

Coverage for making flaws or output fails builds faith and duty. Dependable suppliers also keep long-term stock of spare parts or matching updates to back product life handling.

Customization Capabilities & Industry Applications

Can the Supplier Customize Panels to Fit Your Product Requirements?

Types of Customization Offered:

Tailoring is often vital for unique goods. CDTech can provide different sizes of capacitive touch panels to match the LCD module, and even can provide diversified CTP customisation services, including: support for touch through thick cover glass, waterproof touch(e.g., automotive, charging post, shower devices, etc.), glove touch(e.g., medical and automotive, etc.), active/passive pens(e.g., industrial control and tablet PC).

Tailoring also covers cover lens thickness and form, link choices like USB/I2C/RS232, surface fixes like anti-reflective (AR), anti-glare (AG), or anti-fingerprint (AF) layers, and joining ways such as air gap or full sticking. We offer flexibility in selecting different IC solutions to meet specific needs.

Which Industries Commonly Use Capacitive Touch Panels?

Application Examples Include:

Capacitive touch panels see use in many sectors thanks to their easy handling and toughness:

- Industrial control systems: Require rugged touch interfaces capable of functioning in harsh environments.

- Medical equipment: Demand high precision and hygienic surfaces that are easy to clean.

- Automotive dashboards: Utilize multi-touch functionality with glove-friendly design for driver safety.

These customizations ensure our touchscreens meet the specific demands of various applications, ensuring reliable and precise touch functionality.

Introducing CDTech as a Trusted Capacitive Touch Panel Supplier

What Sets CDTech Apart in the Capacitive Touch Panel Market?

At CDTech, we maintain full in-house oversight of all process controls. This includes precise LCD panel cutting, highly efficient fully automatic polarizer lamination, reliable fully automatic IC/FPC bonding, streamlined fully automatic backlight assembly, advanced fully automatic CTP production, and sophisticated fully automatic lamination production lines.

Every step happens entirely within our facilities. We avoid any external outsourcing. By combining the whole supply chain under one roof, we can thoroughly oversee product quality. At the same time, we ensure timely deliveries.

In addition to our usual items, we take pride in our bendability and skill in giving various tailored fixes on backlight type, FPC(LCD module or CTP), resistive touch panel(RTP) and projected capacitive touch panel(CTP) or anti-reflective(AR) / anti-glare(AG) / anti-fingerprint(AF) coating, or custom cover glass, customized PCB board or a fully custom solution for your product application.

We provide wide tailoring choices including cover glass design (shape, thickness), joining skills (air bonded or optical bonded), link types (USB/IIC), and IC picks suited to your project needs.

All our products are built to meet industrial-grade reliability standards with long-term availability. CDTech’s LCD products have high quality reliability, allowing customers to use them for a long time without easily breaking down.

How Does CDTech Support OEMs Across Different Industries?

Key Support Features Include:

We offer full engineer advice at the design point to aid you in picking the best panel build. Our fast test-making services let you check functions before going to large runs.

To make sure of smooth work through your whole project life, our set account handlers act as your one main contact—boosting reply speeds and keeping project match from beginning to end.

FAQ

Q: How do I verify if a capacitive touch panel supplier is trustworthy?

A: Check their certifications (e.g., ISO 9001), request samples for evaluation, review client references or testimonials, and assess their technical documentation quality.

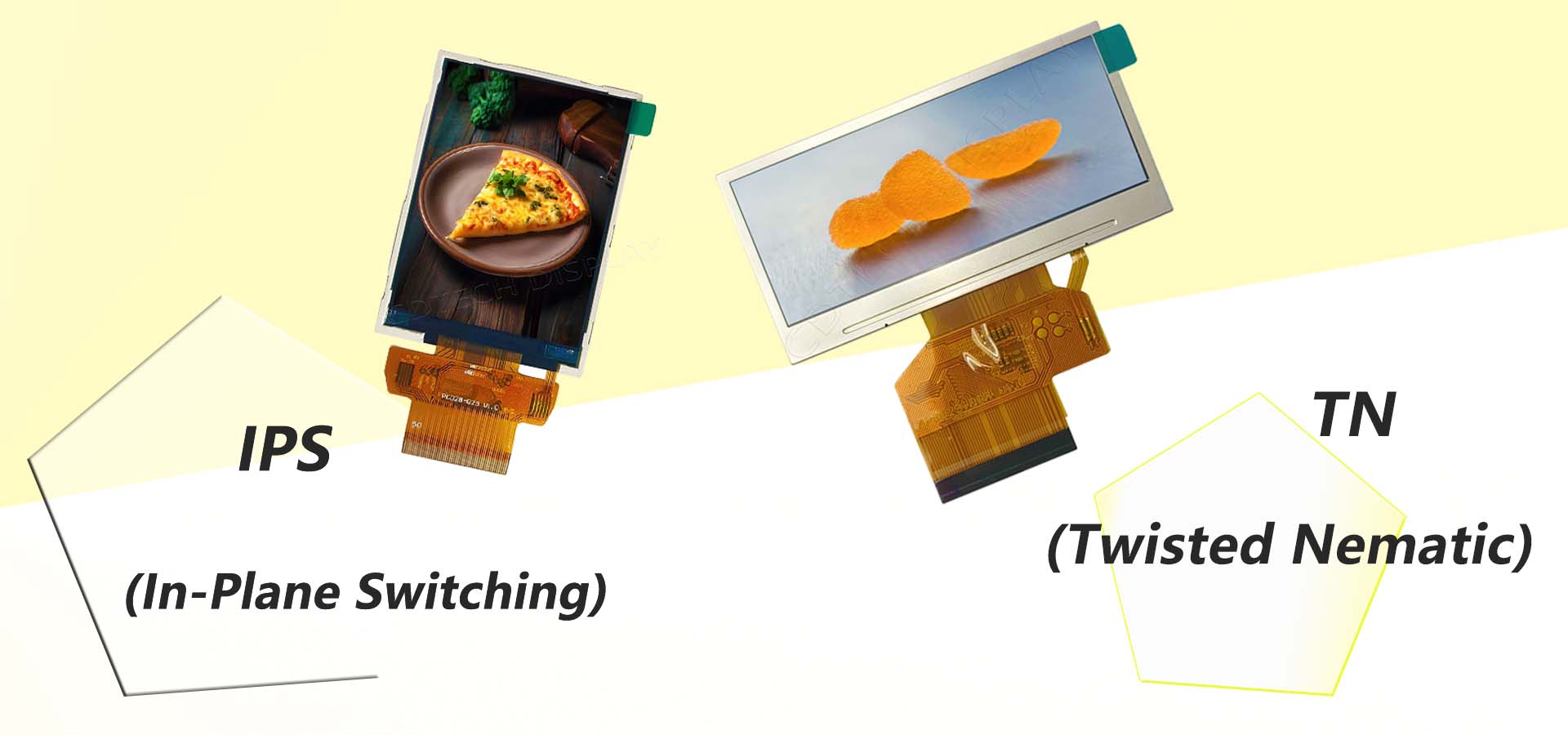

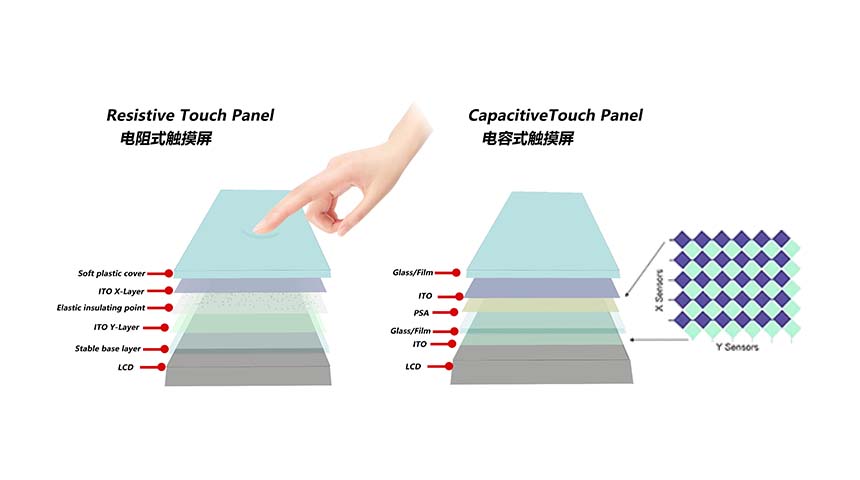

Q: What’s the difference between capacitive and resistive touch panels when choosing a supplier?

A: Capacitive panels offer multi-touch capability and better optical clarity but require more advanced manufacturing. A suitable supplier must have experience handling these complexities.

Q: Can I request custom sizes or interfaces from a capacitive touch panel supplier?

A: Yes. Many reliable suppliers offer customization options including screen size, interface types (USB/I2C/RS232), cover lens printing, and bonding methods tailored to your application.

2026-02-12

2026-02-12  00:00

00:00