How Touch Screen Display Modules are Revolutionizing User Interfaces

Why Are Touch Screen Display Modules Such a Big Deal in Modern Interfaces?

How’s Touch Tech Changing the Way We Use Devices?

Touch screen tech has totally flipped how we mess with digital stuff. Ditching old-school keyboards and mice for slick, gesture-based controls, touch screens have made interacting with devices way more natural. Touch screen display technology is globally gaining prominence due to its easy and interactive use. You can tap, swipe, or pinch to get things done faster on everything from phones to industrial panels.

Touch screen display are going to be integrated with other emerging technologies such as augmented reality (AR) or virtual reality (VR) to create more immersive and interactive user experiences. This mash-up is paving the way for super dynamic, personalized interactions real soon.

What Makes a Touch Screen Display Module So Special?

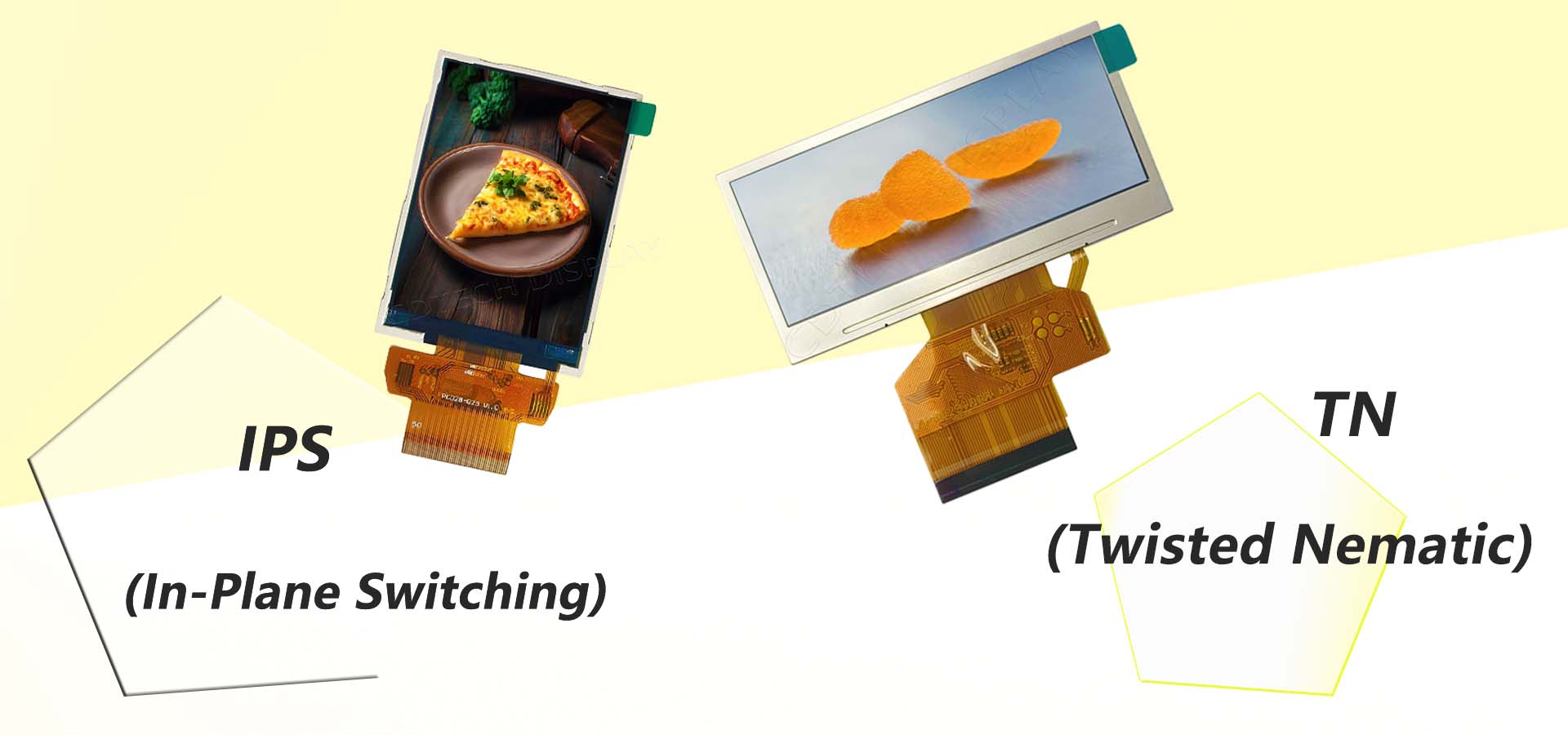

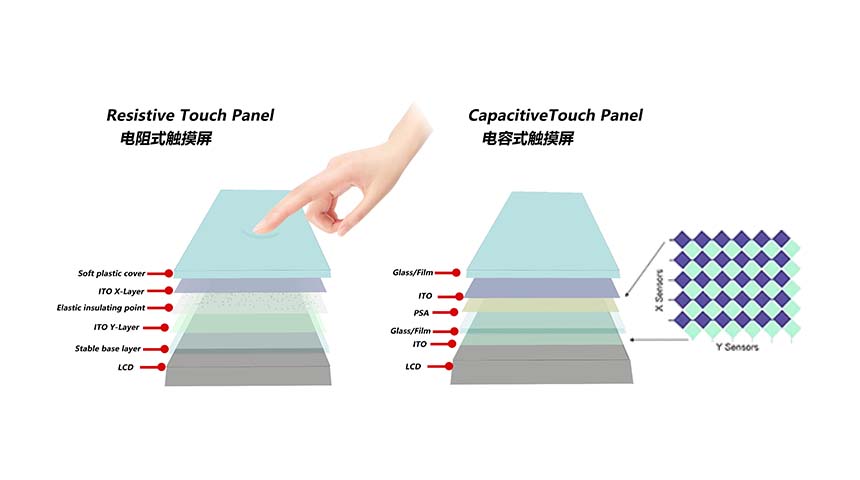

Capacitive vs. Resistive Tech

Touch screen modules come in two main flavors: resistive and capacitive. Resistive screens use layers that pick up pressure, perfect for spots where folks might wear gloves or use styluses. Capacitive screens, though, catch the electric vibes from your fingers and handle multi-touch moves, giving a snappier feel.

Resistive screens are the go-to for tough spots like factories or hospitals because they’re sturdy and shrug off dirt. Capacitive ones rule consumer gadgets for their sleek look and quick response.

Hooking Up with Embedded Systems and IoT Gear

Modern touch screen modules are built to slide right into embedded systems and Internet of Things (IoT) devices. Their small size, low power needs, and flexible hook-up options make them awesome for real-time data tasks. You can plug them in via HDMI, SPI, USB, or whatever your system needs.

Why Touch Screen Display Modules Rock in Everyday Use

Better Experience and Easier Access

Touch screens ditch extra gear like keyboards or mice, making things dead simple. Touch screens reduce the time and effort required for users to perform multiple tasks. They’re easy for everyone—kids, seniors, anyone—because you just tap, swipe, or pinch to get stuff done.

Saving Space and Design Freedom

With fewer clunky parts, touch screen display modules let designers craft sleek, space-saving gadgets. These modules support minimalist product designs without compromising functionality—an essential factor in industries like automotive infotainment or smart home appliances.

Where Do You See Touch Screen Display Modules?

Which Industries Lean on Touch Screen Interfaces?

Healthcare Gear

Medical touch screen display specially designed for medical use and integrated into medical devices are employed in healthcare facilities under different application areas. You’ll find them in patient monitors, EHR terminals, diagnostic imaging, surgical screens, telemedicine setups, and lab tools. They give quick info access and are easy to clean for hygiene.

Retail Kiosks and Checkout Systems

Point-of-sale touch screen display for the retail and hospitality industry play a crucial role in performing payments for goods and services, tracking inventory records on cloud systems, offering loyalty program access, personalized recommendations using AI-driven interfaces—all through a single interactive unit.

Car Dashboards and Navigation

Touch screen display for transportation enable a user interactive interface that is integrated into vehicles for navigation systems, multimedia control panels, climate settings adjustment, or passenger information systems. They keep drivers focused by cutting distractions while dishing out rich media vibes.

How Do Touch Screen Modules Boost Efficiency?

By making controls super intuitive and cutting reliance on clunky buttons or long training, touch screen modules speed up workflows across industries. In factories, touch screens are utilized in control panel systems, human-machine interfaces (HMIs), and automation systems. Operators can check machine stats or tweak settings fast using visual dashboards with snappy touch inputs.

Meet CDTech: Dropping Top-Notch Touch Screen Displays

Who’s CDTech and What’s Their Deal?

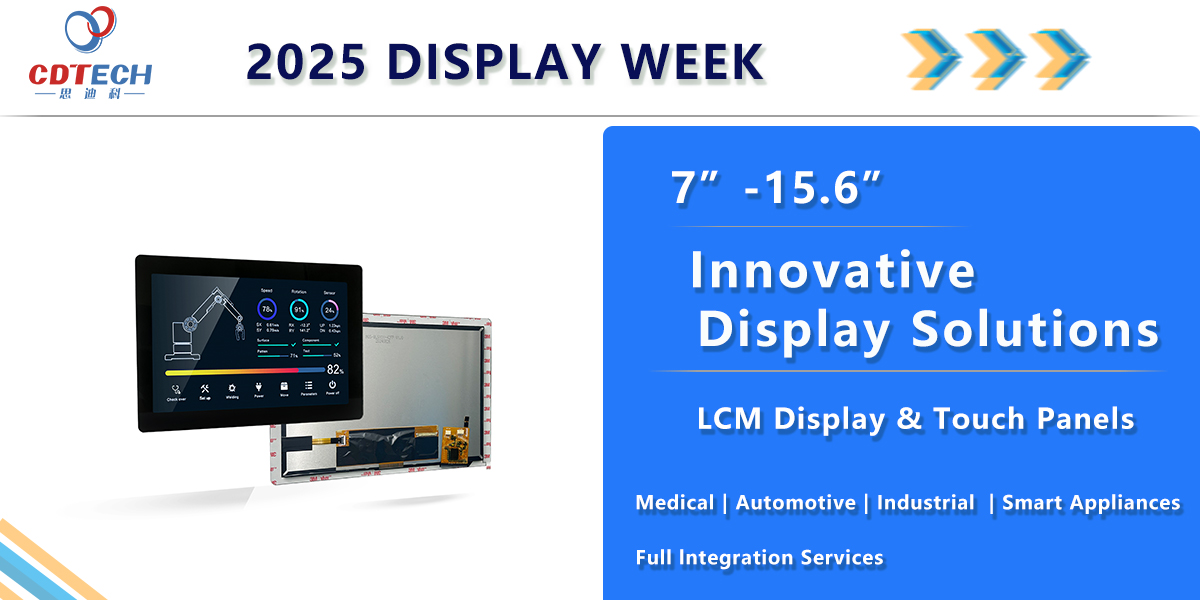

We at CDTech are a national high-tech crew started in 2011, focusing on TFT LCDs, touch displays, HDMI displays, and other slick visual tech. We’re all about delivering standard and custom touch screen module solutions for all kinds of needs.

Our 10,000-square-meter factory has thousand-level dust-free workshops and automated production lines—especially for displays between 1.5 inch~15.6 inch—ensuring we churn out precise gear at scale.

CDTech’s Product Lineup: Standard to Custom

We’ve got products like the 7-inch TN Display with 800×480 resolution, rocking a resistive touch interface and 400 nits brightness—great for embedded systems in all sorts of lighting. We also do capacitive versions per client needs, plus extras like anti-glare coatings or sunlight-readable tweaks.

Why Pick CDTech for Your Touch Interface Needs?

All About Quality, Performance, and Reliability

We roll with big-time certifications like ISO9001 (Quality), ISO14001 (Environmental), ISO13485 (Medical Devices), IATF16949 (Automotive), ensuring our products meet stringent quality benchmarks across sectors ranging from healthcare to automotive.

Used Everywhere from Gadgets to Industrial Gear

Our displays pop up in Industrial Control Equipment, Medical Devices like surgical monitors or diagnostic tools, Smart-Home interfaces, Automotive dashboards, Instrumentation panels, Information Terminals—and beyond.

How Do You Pick the Right Touch Screen Display Module?

What Should You Think About Before Choosing?

Size, Resolution, and Aspect Ratio

Start with your setup’s space limits and how clear you need the visuals. For instance, our 7-inch 800×480 TN display with resistive touch panel is great for compact designs needing solid visibility without eating up room—perfect for handheld diagnostics or small kiosks.

Interface Compatibility (HDMI, SPI, USB)

How it connects matters for fitting into your hardware. Whether you need HDMI output or SPI/USB protocols, our modules offer flexible hookups for embedded systems.

Tough Enough for the Environment

For harsh spots, modules gotta handle temps (-20°C~70°C), vibrations, or dust and water exposure. We build those features in based on where you’re using it, like outdoor kiosks or factory floors.

How Are Devs Working Touch Screens Into Their Gear?

What’s Tricky About Hardware and Software?

Devs sometimes hit snags syncing hardware drivers with OS compatibility, especially with custom UI frameworks on Linux or Android. Getting software gestures to match physical touches also needs tight engineering.

Best Ways to Design UI/UX for Touch Displays

Good UI means keeping things clean but easy to use on small screens. Big buttons spaced out cut down on mis-taps, auto-brightness boosts visibility, and little animations make it feel snappy—all key for a touch-first vibe.

FAQ

Q: What’s the difference between capacitive vs resistive touch tech?

A: Capacitive uses your skin’s conductivity for multi-touch moves, while resistive picks up pressure, so it works with gloves or styluses but usually just single-touch.

Q: Can I use CDTech’s touch screen displays outside?

A: Yup—some models pack up to 1000 nits brightness and anti-glare coatings for sunlight readability if you ask for them.

Q: Are your touch screen displays cool with environmental rules?

A: Totally. All our gear meets RoHS & REACH, so no nasty materials, making them safe for the planet and use in medical or car stuff.

Q: Can you do custom solutions for touch screen displays?

A: For sure—we’ve got standard sizes but also do fully custom options like tweaking interfaces or housings based on your project.

Q: What industries get the most out of your touch screen displays?

A: Our touch screen display modules shine in Industrial Automation, Medical Devices, Automotive Dashboards, Smart Home Interfaces, Retail POS Terminals—anywhere needing reliable, versatile displays.

2025-10-17

2025-10-17  11:50

11:50