LCD Custom Design: Tailoring Display Solutions for Specific Needs

What Is Custom LCD Design and Why Is It Important?

What Does “LCD Custom” Mean?

The term “custom LCD” describes creating a liquid crystal display (LCD) built to fit the specific needs of a product or project. This might include adjusting size, shape, resolution, brightness, connection type or features like mounting holes or frame dimensions. We offer customized LCD OD, LCD AA, FPC OD, backlight option. Customers can choose details like outer dimensions (OD), active area (AA), flexible circuit layout (FPC) and backlight features to match their exact requirements.

Why Pick a Custom LCD Instead of a Standard One?

Off-the-shelf displays are affordable and easy to get, but they often don’t fit specialized products well. A custom LCD brings several benefits:

-

Better performance in specific settings

-

Smooth fit with your product’s design

-

Improved power use

-

Enhanced visuals or touch features tailored to users

Custom displays work best when your product needs unique features that standard options can’t provide, like readability in sunlight for outdoor gear or low power use for battery-driven devices.

Which Industries Gain Most from Custom LCDs?

Custom LCDs are used in many fields where standard displays can’t meet unique functional or environmental needs. Examples include:

-

Vehicle Displays: Car dashboards need tough screens with bright visuals and wide temperature ranges.

-

Smart Appliances: Home devices look better with sleek, brand-specific interfaces.

-

Medical Devices: These require clear visuals and materials safe for sterilization.

-

Industrial Panels: Displays must handle vibration and dust in tough settings.

How Do You Know If a Custom LCD Fits Your Project?

Questions to Ask Before Starting a Custom LCD Project

Before choosing a custom solution, assess your project’s scope and technical needs. Key questions are:

-

What’s the expected production volume?

-

Are there size limits for the display?

-

Will it face extreme heat, cold or lighting?

-

Do you need touch features?

-

What connection type links to your main system?

Answering these early helps decide if a custom LCD is needed or if a standard display will do.

How Do Technical Needs Shape the Design?

Screen Size and Resolution

The display’s size and pixel resolution must match user needs and system limits. Bigger screens may need higher resolution for clear visuals. Smaller devices might use lower resolutions to save power while keeping usability.

Connection and Interface Options

Display connections like SPI, I2C, RGB, MIPI DSI or LVDS must work with your processor. Some projects need built-in features like touch controllers or memory for graphics.

Durability and Environmental Needs

For outdoor or industrial use, displays might need bright backlights, wide temperature ranges, anti-glare coatings or moisture-resistant layers. These factors guide material choices during design.

Meet CDTech: Your Custom LCD Partner

Who Is CDTech and Why Choose Them?

At CDTech, we focus on high-quality custom LCD solutions built for our clients’ needs. Our team works with you from idea to production, ensuring every detail is perfect.

We stand out with:

-

Years of expertise in display technology

-

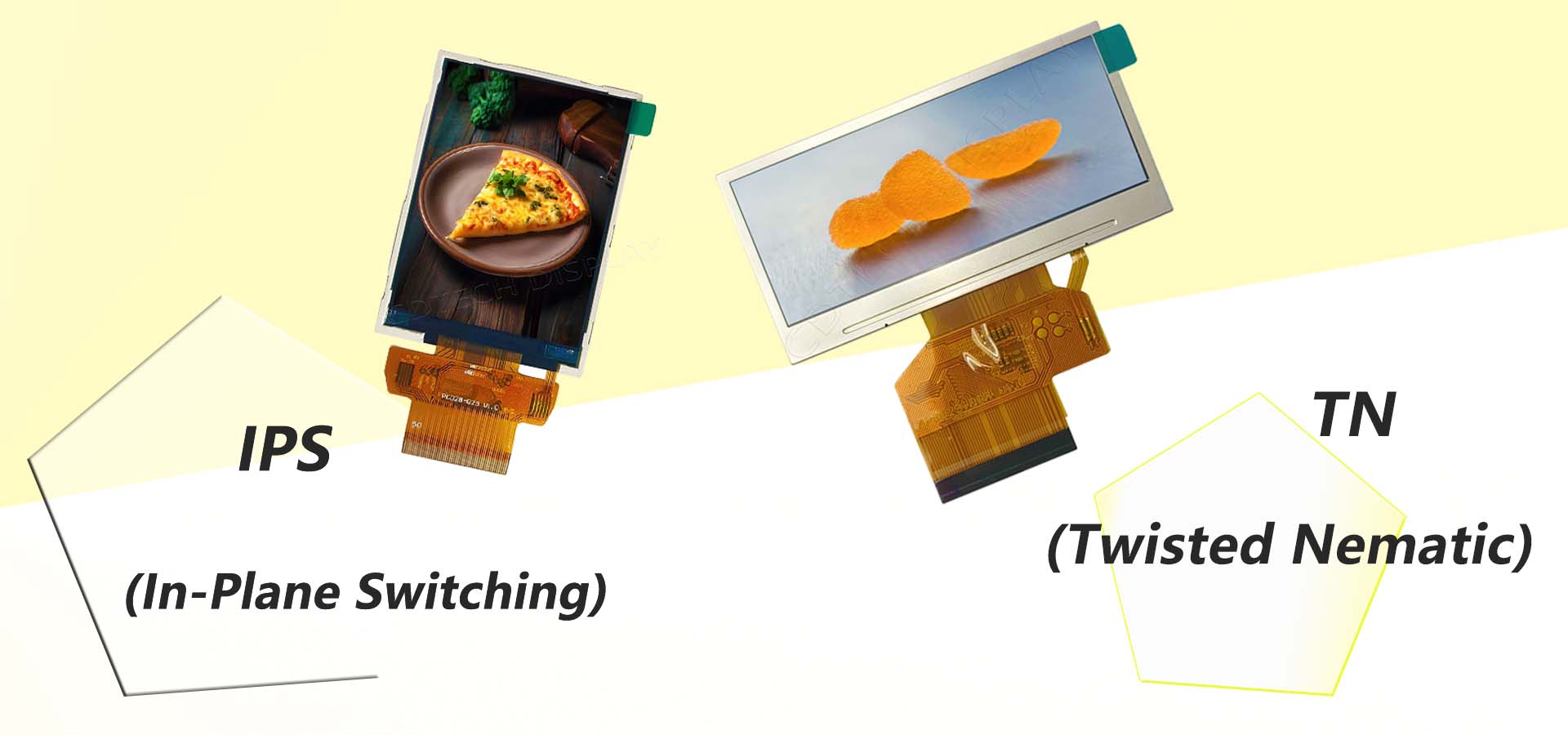

Flexible options for TFT-LCDs, OLEDs and segment displays

-

Full support, including firmware integration

What Custom LCDs Does CDTech Offer?

Segment and Graphic Displays

Segment displays are great for simple readouts, like on thermostats or meters. Graphic displays allow pixel-level control, ideal for icons and basic interfaces.

TFT and OLED Modules

CDTech offers full-color TFT modules from 0.96” to over 10”. For instance, our 4.3-inch TFT display with 480×272 resolution and optional capacitive touch is perfect for industrial control systems.

OLED modules provide better contrast and viewing angles while using less power in dim settings.

Touchscreen Options

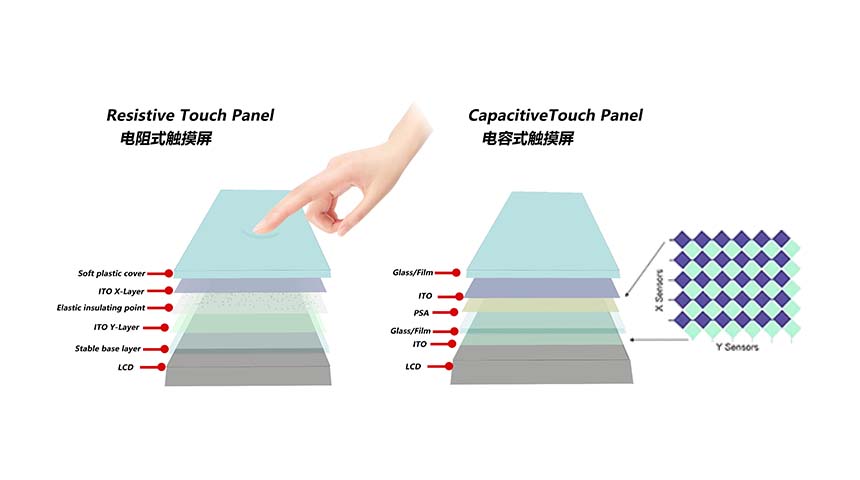

We offer resistive and capacitive touch across our products. Capacitive screens support multi-touch gestures for modern interfaces, while resistive ones work well with gloves in rugged settings.

How Does CDTech Support Your Project?

From start to finish, we provide:

-

Mechanical drawings and 3D models

-

Sample displays for testing

-

Firmware help for smooth integration

-

Supply chain support for steady availability

Our aim is to deliver a complete solution that improves your users’ experience.

Key Steps in Building a Custom LCD

How Long Does a Custom Display Take?

Development takes 6–16 weeks, depending on complexity. Simple changes, like backlight tweaks, are faster than full redesigns needing new tooling.

Phases of a Custom LCD Project

Concept and Requirements

This step defines key details—size, connection type, brightness—and checks for needed certifications (e.g., automotive standards).

Prototyping and Samples

We build test samples based on agreed specs, so you can check performance before final production.

Production and Quality Checks

After approval, production starts with strict testing, including visual checks, electrical tests and stress tests to meet your industry’s standards.

Cost, Timing and Volume Factors

Are Custom LCDs Pricier Than Standard Ones?

At first, yes—but they can save money over time by cutting out unneeded features found in generic displays. Better performance also boosts user satisfaction, adding value.

How Do Volume and Timing Affect Costs?

Larger orders lower per-unit costs due to bulk savings. Rush jobs may cost more than standard timelines.

We work with clients on planning to keep buffer stock, ensuring supply even during global shortages.

Common Challenges in Custom LCD Projects

Frequent Pitfalls in Custom Display Design

Issues like vague specs or mismatched connections can cause redesigns or delays. Early teamwork with skilled engineers helps avoid these problems.

Ensuring Long-Term Supply Stability

CDTech handles this by offering last-time-buy options before parts are phased out, keeping stock of key components and providing replacement options to reduce redesign needs when parts become obsolete.

FAQ

Q: What’s the minimum order quantity (MOQ) for CDTech’s custom LCDs?

A: MOQs depend on complexity but usually start at 1,000 units per year. We offer smaller prototype batches during development.

Q: Can CDTech help with hardware and firmware setup?

A: Yes—we provide support with pinout setup, timing diagrams and sample code libraries when needed.

Q: How does CDTech manage product lifecycles for custom displays?

A: We track component availability and warn you early about end-of-life parts, offering compatible replacements to keep your project running smoothly.

2025-09-12

2025-09-12  11:50

11:50